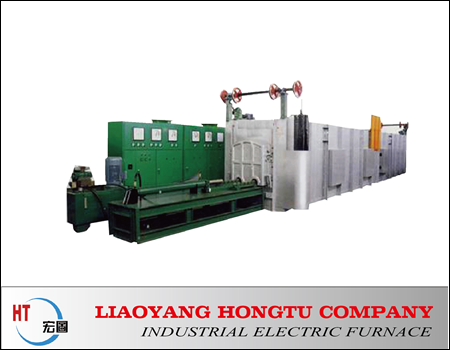

Pusher type electric resistance heat treatment furnace

Brief

This pusher type electric resistance heat treatment furnace is the continuous and automatic heat treatment production line, with the characteristics of unique design, ingenious structure, safe and reliable ,remarkable energy saving etc.

Application field

The production line is well suited for large quantities of the workpiece such as auto spare parts, bearing, gear for quenching and tempering, carburizing.

Structure

This production line mainly consist of fill mechanism, pre-oxidation furnace, heating furnace, carburizing furnace, diffusion furnace, quenching tank, cleaning machine,, tempering furnace, discharging cart and electric control system, etc.Also can configure prewashing machine.

Advantages

1.Using the patented bed charge and oil self-circulation cooling fan , quenching oil air cooling device , workpiece transfer set under oil and fully sealed quench tank, can also set the revolving speed of Mixing motor in different process .

2 Remarkable energy saving

Using the bed charge construction, cancel flame certain to achieve better sealing effect. Small carbon potential fluctuations inside the furnace after charging.

3.Good stability and reliability

Carefully choose the world famous brand components and parts,the equipment has advantages of rational and compact design, simple operation, reliable running, high automation level, advanced craft and very economic energy consumption.

4.The smallest auxiliary installation cost

Using the patented oil self-circulation cooling fan and quenching oil air cooling device, No circulating cooling pool, water pump, cooling tower, water treating equipment, water pipe and other auxiliary facilities are needed

5.Advanced computer management system

Computer system can keep track of charging tray reliably, you can examine the name of the product, quantity, location, discharging time etc. The computer system also can supervise the equipment running status, execute processing simulation and heat treatment data calculation.It is a necessary tool to confirm and optimize technological parameter.

6. Low operating cost, safe and reliable

Advanced technology, good stability, the least amount of auxiliary facilities to insure lowest cost of consumption of energy such as electric power, natural gas , maintenance charge ,auxiliary facilities etc. Perfect security facilities, ensure safety of the operating personnel, equipment and product in operation. Simple and reliable operation to reach a high production performance with long life, to execute heat treatments automatically.